Room 1208, Xinyu Building, Jinghai District, Tianjin, China [email protected] +86-131 02275678

Have you seen a building painted in bright colors and wondered, “How do they do that?” The secret could be a substance known as prepainted steel coil. This special kind of steel is used in building projects in order to make buildings strong, long-lasting, and pretty.

Prepainted steel coil is highly beneficial to the construction industry and is a very user-friendly product. Its primary virtue is that it comes in lots of colors and finishes, enabling builders to concoct whimsical and snappy designs. Prepainted steel coil also has the advantage of maintain long lifespan, and they do not easily get rusty or damage to other buildings and the color remains effective.

So, how is prepainted steel coil made? The process begins with a flat steel coil, which is cleaned to a remove dirt and other gunk. Then the coil receives a special type of primer to make the paint attach more securely. Lastly, a number of coats of paint are applied to the coil and the paint is baked in an oven to catalyze the paint into a strong, durable form.

Turns gymnasiums, playgrounds and roads Buildings not only tough, but also good-looking Prepainted. A splashy finish can make a building pop and catch people’s eyes. The protective coatings on prepainted steel coil prevent rain and sunlight from causing damage that results in a longer lasting, less care-intensive building.

The other wonderful aspect of prepainted steel coil versatility. It is applicable in numerous building areas, such as roofs, walls, gutters and garage doors. What’s more, prepainted steel coil is very easy to install and can be an ideal material for homeowners, builders, and anyone in between.

No matter if you are constructing a new home as a store, factory or even prefab houses, prepainted steel coil seem to be a better and more suitable solution to all these demands. It is a long-lasting and rust-resistant product suitable for many industrial markets, including construction and manufacturing.

Strategically located near Tianjin Xingang Port, one of Northern China's major international ports, we benefit from superior transportation connectivity, enabling efficient global export and supply chain management.

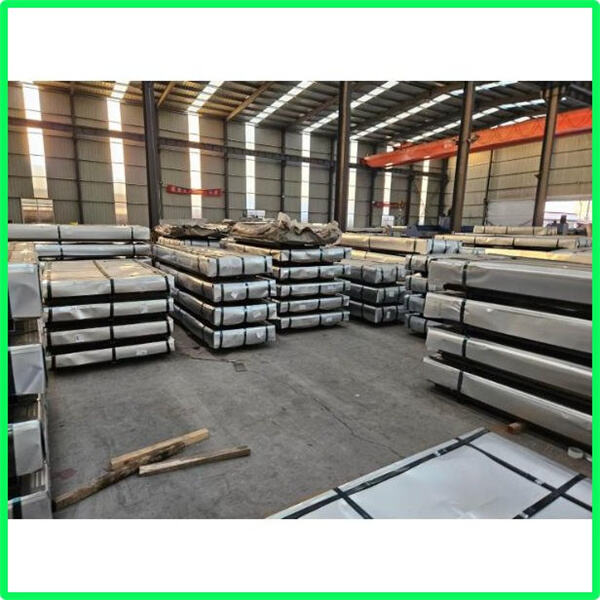

With multiple production lines including 3 hot-dip galvanizing lines and 4 hollow section lines, we boast an annual output of 200,000 tons of galvanized, ERW, seamless, and shaped steel tubes to meet diverse industrial demands.

We are ISO9001 certified and implement strict quality control from raw material to finished product, including dimensional checks, zinc coating tests, and support for third-party inspections (SGS, BV, TUV) to ensure compliance and reliability.

Guided by a "Reputation-based mutual benefit" philosophy, we offer cost-effective solutions without compromising quality, backed by experienced technical and sales teams who provide responsive pre- and post-sales support worldwide.

Copyright © Tianjin Teni Import & Export Co.,Ltd All Rights Reserved - Privacy Policy - Blog