Room 1208, Xinyu Building, Jinghai District, Tianjin, China [email protected] +86-131 02275678

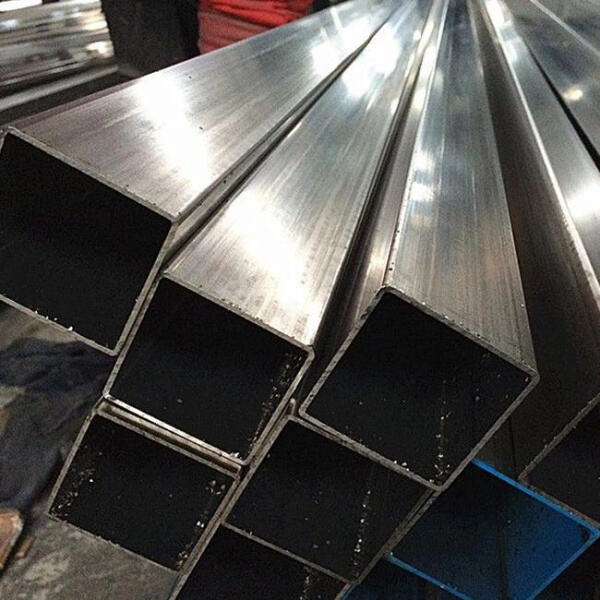

Hollow square tubes are building materials used in building and construction. Attachments These tubes can be assembled in a variety of ways to create stable and sturdy structures. In this post, we are going to examine the benefits of hollow square tubing in the field of construction and engineering.

Hollow square tubing is versatile and can be applied in various ways when constructing a building. They are commonly used in buildings as structural support beams, columns or frames. They are strong and hardy, and a great material for anything you want to build. They are also very easy to cut and shape for a variety of styles, making them very practical for many projects.

One of the main reasons to use hollow square tubing is for its strength and stability. These tubes are capable of carrying a large amount of weight and withstanding a lot of force, which means that they are the ideal type of gas mains for buildings and other structures. And hollow square tubes weigh less than solid steel beams, so they can be easier to handle and move.

Hollow square tubes are also good because they are light but strong. This makes them easy to use and easy to install, and it also ensures that they are long-lasting. The hollow nature of these tubes makes a structure lighter, something that can be useful in some construction projects.

Hollow square tubes are good to excellent for design flexibility. They can be readily cut and shaped to accommodate a particular design, which is often seen with engineered solutions. Designers can use hollow square tube in innovative design with fast and economic way to meet their project requirements.

And then, hollow square tubes are renowned for their sturdy frame. They provide high structural capacity to carry and resist the loads forces of buildings. From being supporting slats or structures to frames or gussets, it has many uses.

We are ISO9001 certified and implement strict quality control from raw material to finished product, including dimensional checks, zinc coating tests, and support for third-party inspections (SGS, BV, TUV) to ensure compliance and reliability.

Guided by a "Reputation-based mutual benefit" philosophy, we offer cost-effective solutions without compromising quality, backed by experienced technical and sales teams who provide responsive pre- and post-sales support worldwide.

With multiple production lines including 3 hot-dip galvanizing lines and 4 hollow section lines, we boast an annual output of 200,000 tons of galvanized, ERW, seamless, and shaped steel tubes to meet diverse industrial demands.

Strategically located near Tianjin Xingang Port, one of Northern China's major international ports, we benefit from superior transportation connectivity, enabling efficient global export and supply chain management.

Copyright © Tianjin Teni Import & Export Co.,Ltd All Rights Reserved - Privacy Policy - Blog