Room 1208, Xinyu Building, Jinghai District, Tianjin, China [email protected] +86-131 02275678

WOW, Galvanized steel coils are some neat stuff! You know, they are put through a special process that makes them hard and resistant to rust. Let’s find out more about what galvanized steel coils are and how they are made, so that you’ll have a better idea as to what you can use them for.

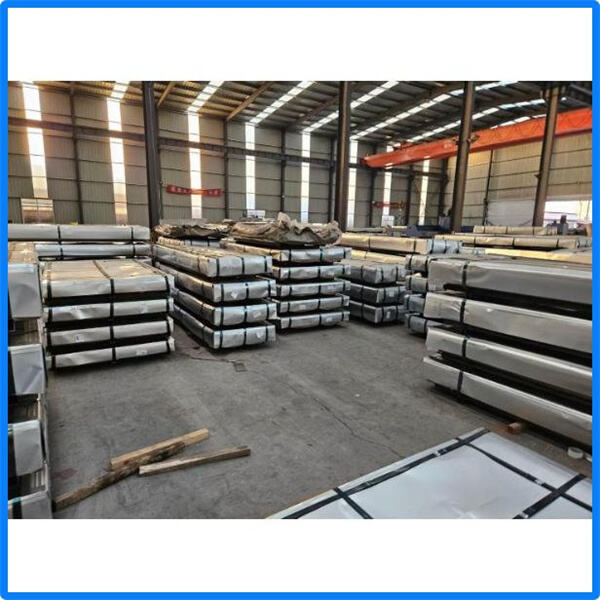

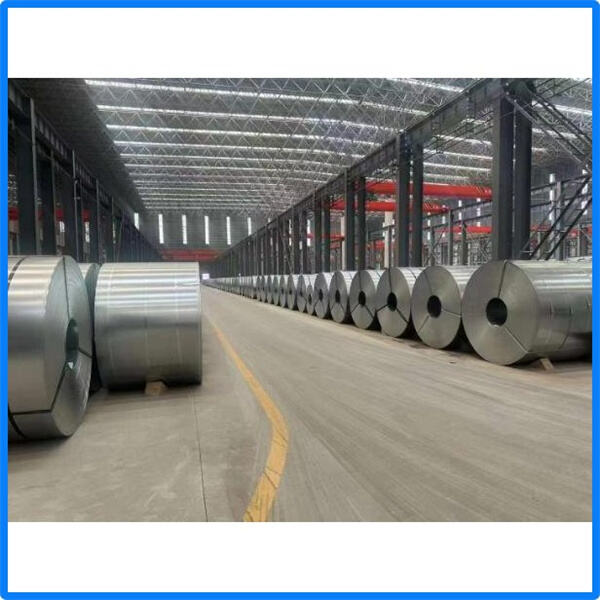

Galvanized steel coils are produced by the process of applying a protective zinc coating to steel. The process is known as galvanization. It acts as a barrier to protect the steel from rust and corrosion. The steel coils are firstly cleaned to get rid of the dirt and oil on its surface. They are then dipped into molten, hot zinc. This coats the steel and creates a protective barrier that prevents it from rusting, even if it gets wet.

Click here for more advices about Copper Coated Galvanized Steel Sheet in construction(describing The Uses and Advantages of Copper Coated Galvanized Steel Sheet).

Galvanized steel coils are widely used in the construction industry, as they are strong and durable and resistant to rust. This means that products in the construction industry that are made from the material are less likely to rust or corrode over time, for example buildings and structures made from the steel coils. They can be molded to take on different shapes. This is why they’re so good for so many types of construction, from roofs to walls to support beams.

There are various types of coatings that can be applied to steel coils; however, each coating has their own reasons for being used. Some of such methods are hot dip, electro galvanization, and continuous galvanization. The most widely used is hot dip galvanizing. It consists in immersing the steel rolls in melted zinc. Electro-galvanizing, meanwhile, which uses electricity to adhere the zinc to the steel. On the other hand, continuous galvanizing involves coating a thin layer of zinc onto the steel as it travels the line.

Galvanized steel coils are used in a variety of industries, from construction to transportation, and even manufacturing, automotive and agriculture. They are sturdy, long lasting and don’t rust, so they are ideal for various jobs. They are utilized in building construction such as roofing, walls, and framing. In manufacturing, they also help produce appliances, furniture and machines. In the automobile industry they are applied to automobiles bodies. In agriculture, they are employed in fences, gates, and implements.

Being resistant to rust and corrosion, galvanized steel coils can be ATSM/EN/JIS standard of these products. This makes them ideal for outdoor equipment and structures that are subjected to sun and rain. For instance, they are commonly applied in fences, guardrails and outdoor furniture. They are also present in marine environments, such as boat trailers and docks, as they can withstand saltwater and moisture. In addition to their resistance to rust, the coils are incredibly strong and won’t be easily damaged by outdoor conditions.

We are ISO9001 certified and implement strict quality control from raw material to finished product, including dimensional checks, zinc coating tests, and support for third-party inspections (SGS, BV, TUV) to ensure compliance and reliability.

Strategically located near Tianjin Xingang Port, one of Northern China's major international ports, we benefit from superior transportation connectivity, enabling efficient global export and supply chain management.

With multiple production lines including 3 hot-dip galvanizing lines and 4 hollow section lines, we boast an annual output of 200,000 tons of galvanized, ERW, seamless, and shaped steel tubes to meet diverse industrial demands.

Guided by a "Reputation-based mutual benefit" philosophy, we offer cost-effective solutions without compromising quality, backed by experienced technical and sales teams who provide responsive pre- and post-sales support worldwide.

Copyright © Tianjin Teni Import & Export Co.,Ltd All Rights Reserved - Privacy Policy - Blog