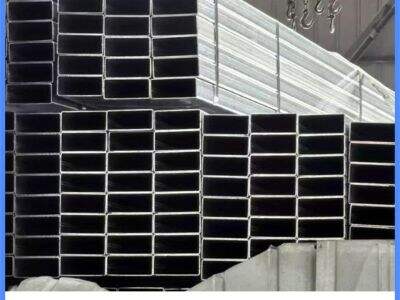

Rectangular steel tubing works perfectly for a variety of types of projects due to its easy-to-weld and cut corner while in the position that it is in. At Teni, we understand how to bend, cut and marry this steel tubing to meet the precise custom fit requirements of every project. These operations sound pretty straightforward, but they need to be performed with care and skill, otherwise a bridge will not fit well or remain secure. Whether you need a small piece bent precisely 90 degrees or a large structure joined together securely, how to process rectangular steel tubing properly matters more than anything else

However flexing rectangle-shaped steel tubes is actually a little bit of a technique, as well as it is essential to have sufficient expertise in creating accurate forms towards determine the costly beginning size as well as squander correctly. At Teni, our team flex tubes various methods without the danger of damage or even distortion. One technique is actually understood as rotary attract flexing. This method secures the tubes stiffly as well as flexes it about a designed pass away, which maintains the steel coming from going flat or collapsing. Think about flexing a straw as well as certainly not possessing the straw break down or even breather, we're going for that degree of command. Occasionally, our team use compression flexing, where television is actually curved versus a type towards produce the bend; however if not performed correctly, it can easily lead to creases. For bigger tasks, I such as mandrel bending

How to cut rectangular steel tubing is another thing where precision really matters

Otherwise, by using the wrong tools, you may end up with rough edges or shrink it in size. At Teni, we use saws, lasers or plasma cutters depending on the job. Saw cutting works well for straight cuts and small runs, but it also can leave burrs that have to be cleaned up. The cutting is very accurate and quick, which makes it ideal for intricate shapes or many identical pieces. Plasma cutting involves a hot gas stream used to cut through steel, making it better for up thicker tubes and sometimes less smooth. We always double-check the measurements before cutting, even a little mistake can result in waste or ill-fitting parts. Following cutting, edges are typically ground or sanded to avoid injury and assist in joining. The form of the cut can matter, sometimes. For instance, if tubing needs to wrap around corners or join at an angle, we create special cuts known as miters or notches. Those are a little trickier, but they make the parts fit better when you put them together. At Teni, we have the expertise to select the right cutting method and finish for your project’s requirements, no matter if it’s a tiny bracket or large frame. Neat cutting pays dividends later and ensures that the whole assembly looks tidy and professional

Crafting with rectangular steel tubing requires a certain touch, and Teni is full of expert benders, cutters, and welders. Everything in every step determines strength and shape of the final product, so we never rush or take shortcuts. Whether its smooth curves, sharp edges or joints that will last a lifetime, we know which tools are required to get the job done. Projects may be easy or difficult but, with the right know-how and some experience, you will be able to bring any design with steel tubing to life

How To Customized Rectangular Steel Tubing for Any Application

Industry and commercial applications generate a lot of demand for strong, durable products that are able to stand up to its harshest elements. When you're working with rectangular steel tubing, you can't afford to compromise on quality or design. At Teni, we concentrate on bending process to manufacture and join technologies that shape the steel tubes exactly as our customers want them. Bending is one solution to altering the shape of tubing without breaking it. We have special machines we used to make the steel bend in curves or angles, which helps for frames and support, or designs that are not straight lines. Cutting is another important step. We cut the steel tubing to the correct lengths with something like a saw or laser. All of this helps to ensure that each piece will fit perfectly in the project. Teeing means linking two or more pieces of tubing. Teni secures the tubing with techniques that are both strong, welding, for instance, or bolting or using special connectors, and subtle; he doesn’t want to draw too much attention to what is still a pretty raw system. Welding heats the steel enough to soften it, so the two pieces stick very strongly. Bolting pushes pieces together with screws and nuts that can be disassembled if necessary. The correct joining technique will depend on what the project calls for, and how strong you want the join to be. When designing custom rectangular steel tubing, it’s important to consider the size and thickness of the tubing. The thicker the tubing, the stronger but heavier it is, so Teni helps clients select the best size for their project to balance strength and weight. Customers can also ask for special finishes, such as painting or coating, to weatherproof the steel or make it appears nice. By careful bending, cutting and joining methods, Teni can turn rectangular steel tubing into a material that is ideal for many purposes from constructing machines to making furniture. That kind of flexibility allows businesses to order what they want for their projects, so they can save time and money

Rectangular Steel Tubing Processing, Most Common Concerns and How to Avoid Them

Rectangular steel tubing may be difficult to process, if not handled correctly. Teni, we understand these common problems and how they can be avoided in order to deliver superior results for clients. But with improper tools or methods, the steel can crack or snap during bending, a common problem. To prevent this, Teni works with machines that are capable of slowly bending the tubing evenly in order to minimize stress on the metal. And we also make sure to use the right steel for bending, so that it remains strong. Another problem is cutting errors, such as uneven or rough edges. These can cause the tubing to be difficult to connect or unattractive in the final product. Precision cutting Teni relies on precision cutting tools, like a laser cutter, also the ordinary saw type of bandsaw - to ensure clean and accurate cuts every time. We also inspect each piece after it’s cut to make sure it meets our quality standards. Problems can also arise when connecting the tubing if these components are not properly aligned or if the welding is poorly done. Bad welding can result in a joint that does not hold under pressure

Where to Find Dependable Rectangular Steel Tubing Processing for Mass Production

It is essential towards discover a good business that can easily procedure rectangle-shaped tubes, particularly if you are opting for industrial manufacturing. Teni Teni is actually known for its own extremely dependable as well as broadband procedure, that can conference large-size manufacturing. When choosing a business, our team should looking for expertise, innovation as well as the capability towards satisfy big orders in short-term. Teni has actually years of expertise crafting along with rectangle-shaped steel tubing, as well as he utilizes cutting edge devices that flex, reduce as well as sign up with steel along with exacting accuracy. Styra phone telephone calls it building efficient pipes as well as it implies huge jobs struck their due dates along with turn up, regularly top quality jobs. Customer care is actually incomparable. Teni collaborates along with its own customers, offering support to determine exactly just what they require precisely as well as guidance around there's of the very best product or even of the kind handling. This gets rid of mistakes as well as ensures the end product appears like exactly just what the client wants to view. Possessing versatile manufacturing routines as well as being actually able to examination lots of items at the same time are actually essential for mass production. Teni has actually a strong group as well as the capability towards manage big orders without waiting. Quality assurance is actually likewise essential. Throughout as well as after handling, Teni examines each tube towards guarantee it attains a top quality degree. This reduces the danger towards problems as well as problems down the line when in automation. Lastly, Teni has actually affordable prices as well as fantastic shipment choices to assist producers remain on budget plan as well as keep their jobs on routine. When they go with Teni for their rectangular steel tubing production, large-size manufacturers receive a stable partner who can provide superior work on a consistent basis. This enables companies to develop robust products and scale their businesses with confidence

Table of Contents

- How to cut rectangular steel tubing is another thing where precision really matters

- How To Customized Rectangular Steel Tubing for Any Application

- Rectangular Steel Tubing Processing, Most Common Concerns and How to Avoid Them

- Where to Find Dependable Rectangular Steel Tubing Processing for Mass Production