Room 1208, Xinyu Building, Jinghai District, Tianjin, China [email protected] +86-131 02275678

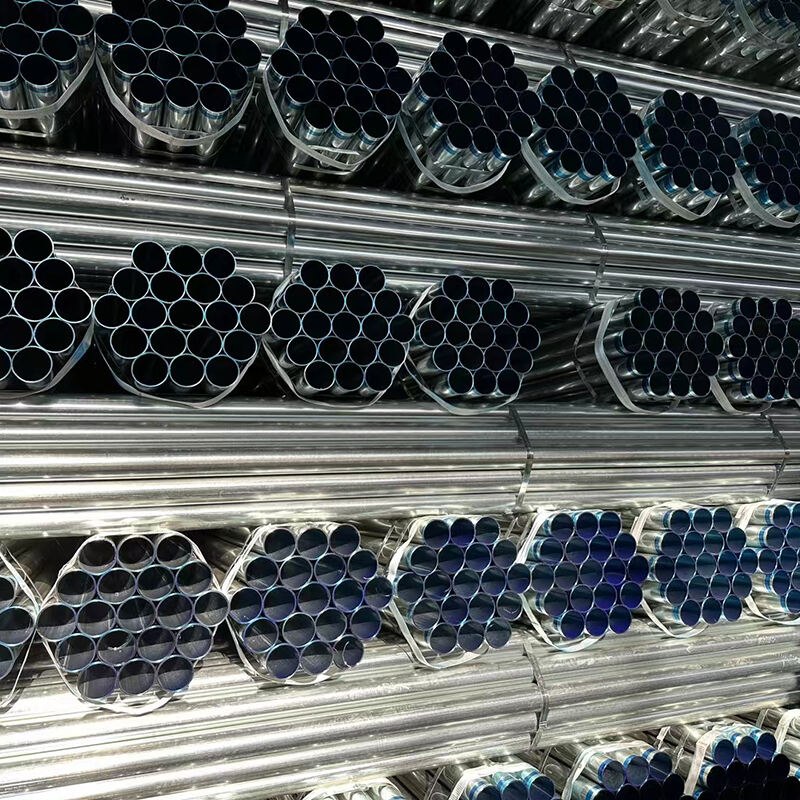

GI coated pipes are profiles of a steel plate that have a coating of zinc to protect them from rust. These are extensively used in several industries for multiple purposes. Let’ see the further details of GI coated pipes.

GI coated pipes are rigid, weather resistant, and long lasting. The result is they are less likely to get rusty or degrade when coming into contact with liquids/other corrosive material. Companies are able to save time and money by using GI coated pipes, guaranteeing that their pipelines and facilities will have a longer lifespan and need less maintenance.

GI coated pipes are widely used in a variety of industries such as the construction industry, agricultural industry, automobiles industry and so on. Like other low carbon pipes GI pipes are also used in drainage and water lines, heating systems, major & minor irrigation system, structural applications (columns/ beams etc) along with cages and scaffolding. GI pipes are also used for other applications ie.ordinary pipework or scaffolding.

The process of making galvanized GI coated pipe for anti-corrosion purposeehenry steel gi pipe gi pipe galvanized gi pipe high quality products.

GI Coated pipe GI Pipes are a type of coated steel pipe that are coated with zinc to prevent rusting and corroding. This action, known as hot-dip galvanizing, results in a protective coating that is strong, adherent, and provides long-term protection for the underlying steel. Companies are able to make the life of a pipeline and structure longer through the process of galvanizing GI coated tubes.

One of the primary benefits of using GI coated pipes in water and gas pipeline services is such that they tend to resist strong hydraulic work. This ensures that they won't develop leaks, which would force costly repairs less time working. GI pipes are also low in cost, and are easy to install and maintain making them the perfect choice for many companies.

In order to maximize the life of GI coated pipes, it is necessary to maintain them well. This includes frequent monitoring of the pipes for damage or corrosion, maintaining the lines when necessary, including repairs as necessary. With proper attention, GI coated pipes are allowed to serve you a long life-time, thus maximizing your investment in the rugged and versatile pipe.

We are ISO9001 certified and implement strict quality control from raw material to finished product, including dimensional checks, zinc coating tests, and support for third-party inspections (SGS, BV, TUV) to ensure compliance and reliability.

With multiple production lines including 3 hot-dip galvanizing lines and 4 hollow section lines, we boast an annual output of 200,000 tons of galvanized, ERW, seamless, and shaped steel tubes to meet diverse industrial demands.

Guided by a "Reputation-based mutual benefit" philosophy, we offer cost-effective solutions without compromising quality, backed by experienced technical and sales teams who provide responsive pre- and post-sales support worldwide.

Strategically located near Tianjin Xingang Port, one of Northern China's major international ports, we benefit from superior transportation connectivity, enabling efficient global export and supply chain management.

Copyright © Tianjin Teni Import & Export Co.,Ltd All Rights Reserved - Privacy Policy - Blog