Room 1208, Xinyu Building, Jinghai District, Tianjin, China [email protected] +86-131 02275678

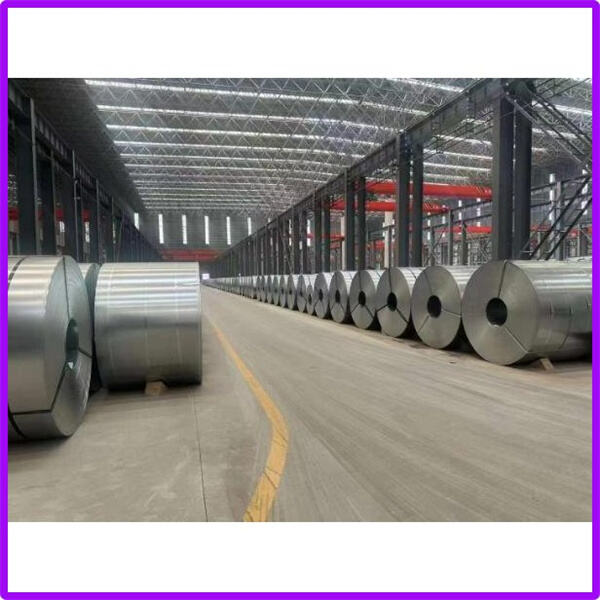

Strong and rust-proof are a big deal when we’re talking about the types of materials you use for building stuff. One excellent option which won't rust and will be durable is galvanized sheet coil. This special metal is prepared for longevity and good for many applications.

There are a lot of good things about applying galvanized sheet coil in construction. For one, it’s coated in a layer of zinc that helps it resist rust—so if you’re using these in an outside building that’s exposed to the elements, you won’t find that your tools have rusted in their place. Additionally, galvanized sheet coil is easy to drill, form and weld to customize your project. For this reason, it is favoured by builders and labourers.

Galvanized sheet coil is an important ingredient for many industries because of its strength and resistance to rust. It is widely used in the construction industry as material for roofs, walls, and support structures. Galvanized sheet coil is used in the car industry to make car bodies and parts. (And it’s used in agriculture for things like grain bins, fences and equipment.)

It is important that you take care of and store your galvanized sheet coil correctly! And remember to wear gloves when moving the material — this will prevent you from cutting yourself and also keep dirt and grease off the surface. If you have galvanized sheet coil, put it on a dry and airy place to prevent it from catching moisture that can turn it into rust.

A few processes are often performed on galvanized sheet coil to increase its tensile strength and its resistance to tearing. First, the steel coils are cleaned and treated with a special solution to remove the dirt. The coils are then dipped in hot, molten zinc to protect the steel from rust. At last, the coated coils are cooled and cut into different size and shapes for other use.

Strategically located near Tianjin Xingang Port, one of Northern China's major international ports, we benefit from superior transportation connectivity, enabling efficient global export and supply chain management.

We are ISO9001 certified and implement strict quality control from raw material to finished product, including dimensional checks, zinc coating tests, and support for third-party inspections (SGS, BV, TUV) to ensure compliance and reliability.

With multiple production lines including 3 hot-dip galvanizing lines and 4 hollow section lines, we boast an annual output of 200,000 tons of galvanized, ERW, seamless, and shaped steel tubes to meet diverse industrial demands.

Guided by a "Reputation-based mutual benefit" philosophy, we offer cost-effective solutions without compromising quality, backed by experienced technical and sales teams who provide responsive pre- and post-sales support worldwide.

Copyright © Tianjin Teni Import & Export Co.,Ltd All Rights Reserved - Privacy Policy - Blog