Room 1208, Xinyu Building, Jinghai District, Tianjin, China [email protected] +86-131 02275678

A106 seamless pipe and gi tubing can be used in many kinds of industries. All externally visible welds are removed to make it seamless, which is of high strength and long life. Tends to be the top choice for work that's under a lot of pressure, wig because it can put up with a lot without breaking.

A106 seamless pipe is recommended for high pressure applications gi pipe, since it can handle a lot of pressure without breaking. This is good for industries like oil and gas. It is also heat resistant, so it performs well in hot conditions. In general, A106 seamless pipe is the best choice when specifications call for higher strength, such as in a high pressure situation.

There are different grades of A106, such as A, B and C, and each grade offers varying features. Some are better suited for specific tasks and it’s important to pick the one that’s right for you. Some are better for high T some are better for high P for instance. When picking a grade of A106 seamless pipe, think about what the job demands.

To ensure the A106 seamless pipe gi pipe 1 2 is good quality, purchase from a reliable supplier. This helps ensure that the pipe is of high quality and will function as expected. It’s also crucial to check the pipe before using it to ensure there are no defects. And finally, correct installation and maintenance are all obviously important for the pipe to last. A regular check and some maintenance helps to avoid and prevent problems.

Proper installation and maintenance of A106 seamless pipe is critical in order for the pipe to last and function safely. If not installed properly, it can leak or shatter and be costly to repair. Common preventive measures like inspections and cleaning can help head off these problems. These are just a few tips to help ensure that a company’s A106 seamless pipe is going to last many years.

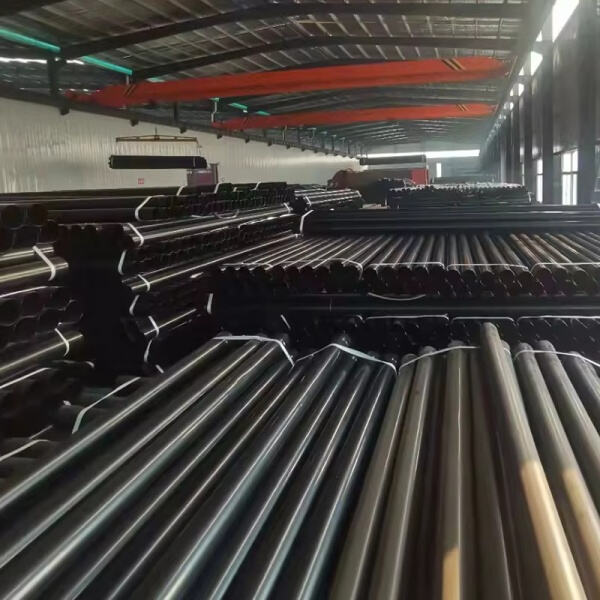

With multiple production lines including 3 hot-dip galvanizing lines and 4 hollow section lines, we boast an annual output of 200,000 tons of galvanized, ERW, seamless, and shaped steel tubes to meet diverse industrial demands.

We are ISO9001 certified and implement strict quality control from raw material to finished product, including dimensional checks, zinc coating tests, and support for third-party inspections (SGS, BV, TUV) to ensure compliance and reliability.

Strategically located near Tianjin Xingang Port, one of Northern China's major international ports, we benefit from superior transportation connectivity, enabling efficient global export and supply chain management.

Guided by a "Reputation-based mutual benefit" philosophy, we offer cost-effective solutions without compromising quality, backed by experienced technical and sales teams who provide responsive pre- and post-sales support worldwide.

Copyright © Tianjin Teni Import & Export Co.,Ltd All Rights Reserved - Privacy Policy - Blog