When we talk about the GI pipes and PVC pipes, for different pipe applications, there are many factors to weigh up against each other., in general, let us compare their durability/cost/applicability between these two types of pipes: Knowing the differences between GI pipes and PVC pipes can help wholesale buyers to make proper purchasing decisions according to their specific requirements and preferences.

Let’s Compare GI Pipes with PVC Piping Durability for Wholesalers

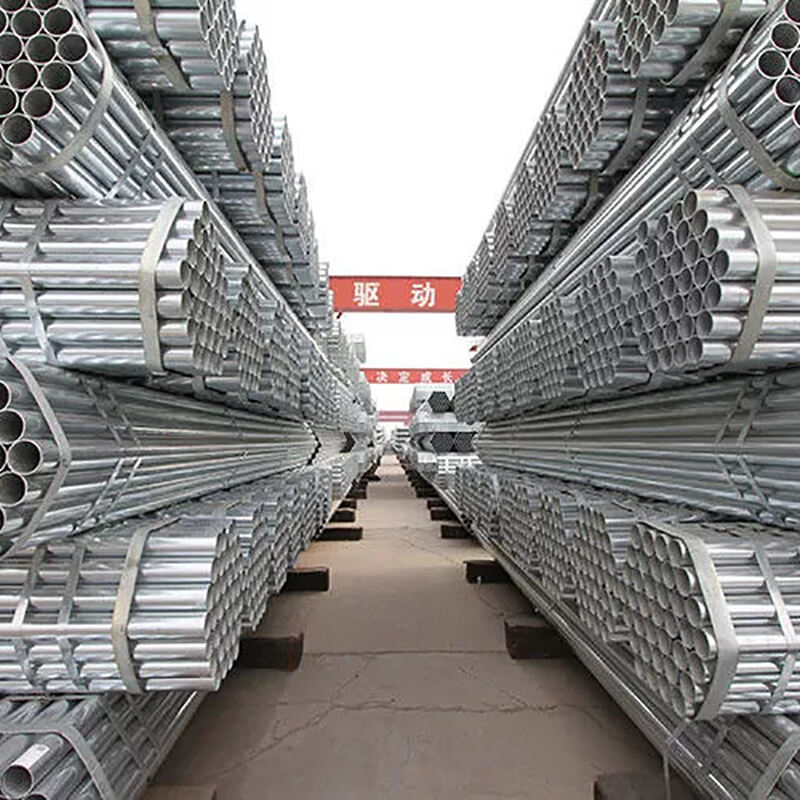

GI Pipes, or galvanized iron pipes, just like the name suggest are useful for their strength and durability. These tubes are constructed from steel and have a protective layer of zinc applied to protect the pipe from corrosion and rust. GI pipes are therefore perfect for both outdoor and interior usage because they can be subjected to the circle of moisture or chemicals. The zinc layer is responsible for protecting the steel from rust and corrosion, which are enemies of any plumbing system.

PVC pipes, or Polyvinyl Chloride pipes, on the other hand are lightweight and immune to chemical erosion. Although, PVC pipes are not as strong as GI pipes but they have the sustainability and longevity. PVC pipes are widely used for plumbing in drainage, waste and vent applications because it does mot rust of corrode. PVC conduits are flexible, too: they are easy to install and bend around obstructions when the job calls for it.

Knowing the Cost Variation between GI and PVC Pipe

Galvanized Steel Pipe as compared to PVC pipe. If the GI is used in pipe then these further will be a process that involves Oiling, cooling, drying and hanging of coiled strip. Form the above comparison, they can find their according production processes and relative materials. But with durability and long life, GI pipes could prove to be an economical solution in the long run; especially for applications where pipes are subjected to severe conditions or requiring high strength.

PVC pipes are also cheaper than GI pipes. The manufacturing process for PVC pipes is simpler and involves fewer materials, which can make it less expensive. PVC may not be as sturdy or durable as GI, but it is also affordable and highly reliable for serving various purposes. PVC pipes are light and easy to carry, which would also help save cost for wholesale buyers.

In the battle of GI pipes vs PVC pipes, wholesale buyers should take into consideration project-specific needs, such as how much durability is needed or how much are willing to spend for a certain application. Both GI & PVC pipes have its own pros and cons they can be used as per the application. By being able to distinguish between these two varieties of pipes, buying in bulk buyers can be certain that they are becoming exactly what their company requires while staying inside the limitations of a given budget.

Types of Pipe Material for High Pressure Application Requirements

When selecting the best pipe for your requirements, there’s several factors to consider. One of the primary concerns is the longevity of the pipe. GI Pipes, known as or GI Pipes are popular for their strength and durability. Corrosion resistant and long lasting, these screws are a reliable choice for your project that requires high strength. PVC (polyvinyl chloride) pipes, on the other hand, are easy to handle and install. They are also corrosion-resistant and can withstand high pressure, so that they are widely used.

Cost is another consideration when comparing GI pipes and PVC pipes. Pricing of PVC pipes is normally cheaper than that of GI but are less tough. PVC on the other hand, is cheaper and easier to install, so it tends to be a budget-friendly choice for many applications. When you're choosing a pipe material for any use, it's important to think about the buy-in price and what exactly your project needs.

Study to Establish the Applicability of GI Pipe versus PVC Pipe in Various Locations

Both GI Pipe and PVC Pipes have their own strengths and limitations in various environments. GI pipes are better for outdoor than indoor use. It has good durability and corrosion resistance for water pipes, fuel pipe, electrical conduit and a lot more. On the contrary, PVC pipes are appropriate for indoor use only and have to be kept away from outdoor conditions. Both are light and easy to install, and commonly found in the home's plumbing-vent system.

When deliberating between GI pipe and PVC pipes for various applications, ensure that you take into account your project needs. If you’re in the need of a pipe that could be used outside, then galvanized iron is probably your pick. If you are seeking an economical and easy to install option for indoor uses, then PVC pipe is certainly the go-to alternative.

Comparison between GI and PVC for Industrial Use

Can be looked at in industrial application: Example Industrial product selection between GI and PVC are based on required the demand of the work. GI pipes are more ideal for industrial purposes which require strength on a large scale. They can accept high pressure and perform well in corrosive environments to complete an industrial piping system. PVC pipes, meanwhile, are so light and simple to install they are used in countless industrial settings.

When selecting between GI pipes and PVC for industrial use, you will need to keep in mind the specific requirements of your project. If strength and durability are concerns, then GI pipes can be the ideal choice. If cost and ease of installation are more important, consider PVC pipe. In the end, the application mentioned above will dictate which type of pipe (GI or PVC) is suitable for any given industrial project.

Table of Contents

- Let’s Compare GI Pipes with PVC Piping Durability for Wholesalers

- Knowing the Cost Variation between GI and PVC Pipe

- Types of Pipe Material for High Pressure Application Requirements

- Study to Establish the Applicability of GI Pipe versus PVC Pipe in Various Locations

- Comparison between GI and PVC for Industrial Use