Room 1208, Xinyu Building, Jinghai District, Tianjin, China [email protected] +86-131 02275678

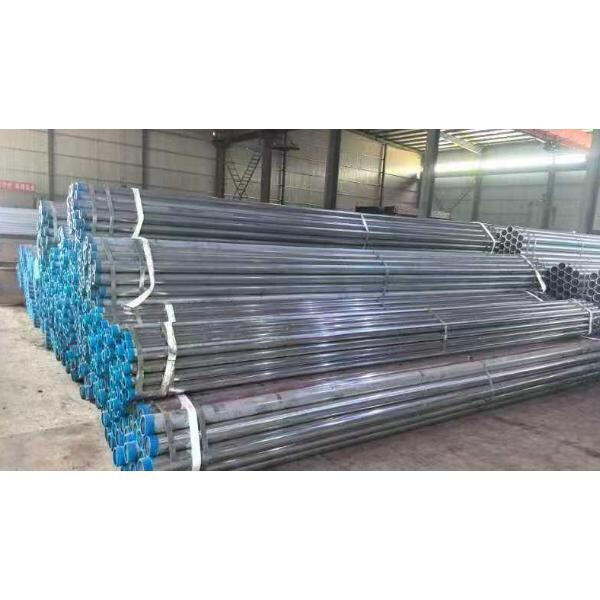

Teni gi pipe are metal pipes that are coated with zinc to minimize rust and corrosion. They are commonly utilized in plumbing and water supply applications. Threading GI Pipes Threading GI pipes is cutting the screws on both sides of the pipe. This ensures you can easily connect it to other pipes and fittings. Cutting threads has an important place in plumbing and helps create strong, tight connections.

Correct threading is of utmost importance for leak proof joints in Teni gi pipe 2 inch system. Pipes that aren't threaded properly will let water leak. This is potentially harmful to its walls, floors, and other parts of a building. Your plumbing system will function well and leaks will be prevented by using the right GI pipes.

Cross-threading is yet another problem associated with Teni gi pipe 1 2 threading. That occurs when the threads are not properly aligned, creating a weak joint. Don't let this happen, ease into tension with straight threading and even pressure.

The other issue is over-tight can wear away the threads and lead to leaks. To prevent this from happening, stop tight when the 1 inch gi pipe are firmly connected.

When choosing fittings for your threaded 4 gi pipe, you must match the size and thread type of both the fittings and the pipes. These fittings should also have strong materials that clip into place for a secure connection. And don’t forget to inspect the pressure rating of the fittings to ensure that they can support your home’s water pressure. Read on for our top picks and purchase just the fittings or a full system to put your mind at ease.

Guided by a "Reputation-based mutual benefit" philosophy, we offer cost-effective solutions without compromising quality, backed by experienced technical and sales teams who provide responsive pre- and post-sales support worldwide.

Strategically located near Tianjin Xingang Port, one of Northern China's major international ports, we benefit from superior transportation connectivity, enabling efficient global export and supply chain management.

With multiple production lines including 3 hot-dip galvanizing lines and 4 hollow section lines, we boast an annual output of 200,000 tons of galvanized, ERW, seamless, and shaped steel tubes to meet diverse industrial demands.

We are ISO9001 certified and implement strict quality control from raw material to finished product, including dimensional checks, zinc coating tests, and support for third-party inspections (SGS, BV, TUV) to ensure compliance and reliability.

Copyright © Tianjin Teni Import & Export Co.,Ltd All Rights Reserved - Privacy Policy - Blog